If you have any question, please contact us

If you have any question, please contact us

Beijing Zhongcheng Metallurgy High-Temperature Materials CO., LLC( shorted as ZCMCO) is a refractory company who focuses on the consulting, designing, installation, research and development for high-temperature industry. We have an annual output production line of 180,000 tons of shaped products and 100,000 tons of unshaped products, main products are heavy density refractories, light weight refractories and unshaped refractories.

The machines in factory are well equipped. We have advanced automatic equipment, advanced production technology, strong technical staffs, perfect quality checking system, we also can provide product supervision services to customers.

The company strives to build a new high-efficiency, energy saving, emission reduction, green and environmental protection high-quality development system, so that the company has achieved considerable development. Products cover the steel industry, construction industry, non-ferrous industry, raw refractory materials and other fields, exported to the United States, Japan, South Korea, India, Iran, Vietnam, Turkey, Malaysia and Indonesia and other international markets, has been unanimously recognized by customers both at domestic and abroad.

In order to meet the personalized needs of customers, we have complete testing equipment and professional testing personnel, and has passed ISO9001 quality management system certification, providing sufficient guarantee for product quality. According to the production process, quality control points include the following:

1. Raw material quality management - Analyze the chemical composition of each batch of purchased raw materials to ensure that they meet the requirements of the product process, and enter different warehouses according to different materials to avoid mixed grades of materials;

2. Semi-finished product quality management - Inspect the appearance size, distortion, cracks and other defects of the bricks, record the inspection results of the semi-finished products, sign for acceptance if they are qualified, and scrap them for grinding if they are not qualified;

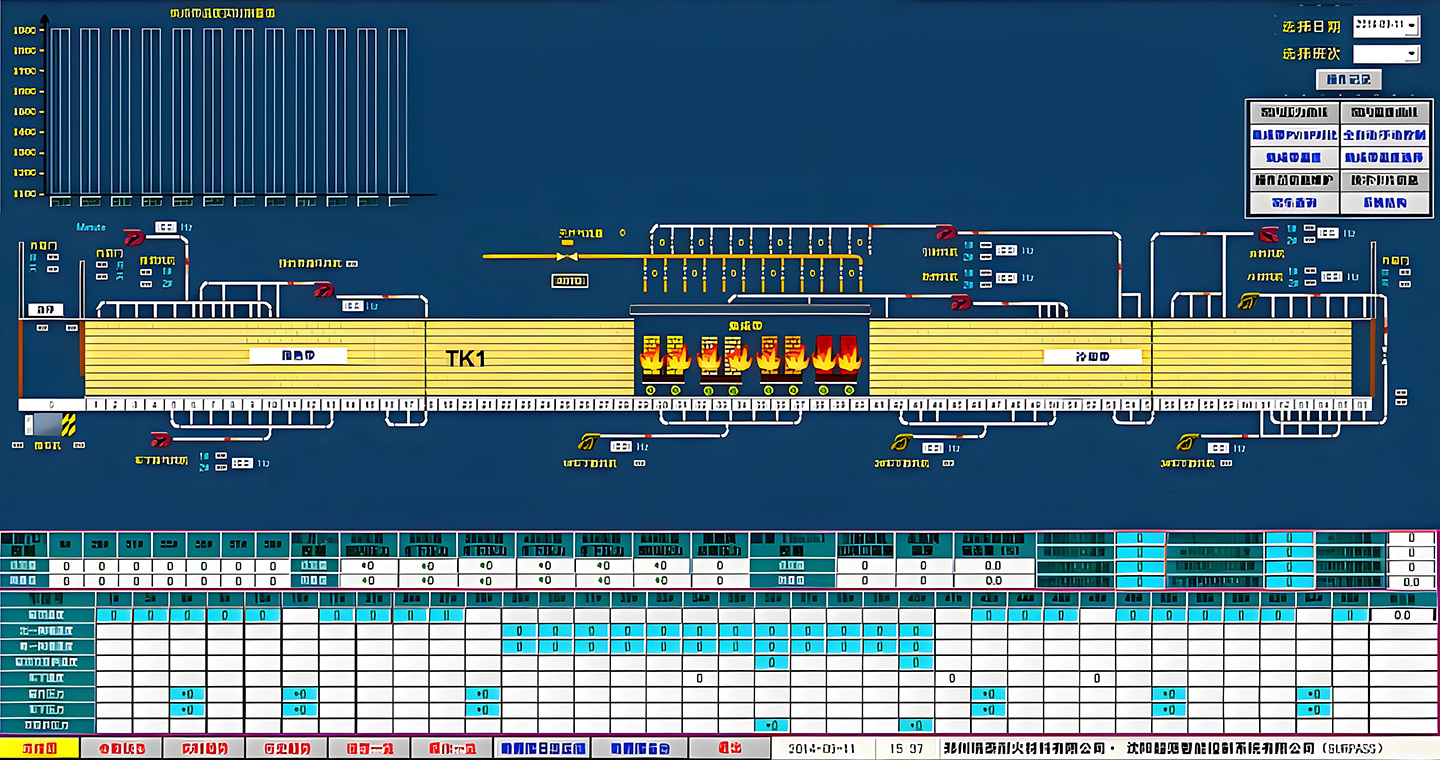

3. Product sintering quality management - the product's sintering temperature and holding time are strictly controlled in accordance with the product process instructions, and the sintering temperature curve is measured and recorded;

4. Finished product quality management - Inspect the products according to the size requirements of the product drawings, and also check for appearance defects such as distortion, cracks, missing corners, etc., mark and classify qualified products; then conduct sampling and testing according to different materials, and issue Test Report;

5. Packaging quality management - Pack products according to customer requirements to ensure that they meet customer packaging standards and meet railway and sea transportation requirements to ensure that products are delivered to customers without damage.