If you have any question, please contact us

If you have any question, please contact us

Hot blast stove is the blast furnace heating air equipment, is one of the main supporting equipment for ironmaking blast furnace, generally a blast furnace with 3 to 4 hot blast stoves, the role of the hot blast stove is to continuously provide the blast furnace with more than 1000 ℃ of high temperature hot air, advanced hot blast stove wind temperature can reach 1300 ℃.

Hot blast stove is the blast furnace heating air equipment, is one of the main supporting equipment for ironmaking blast furnace, generally a blast furnace with 3 to 4 hot blast stoves, the role of the hot blast stove is to continuously provide the blast furnace with more than 1000 ℃ of high temperature hot air, advanced hot blast stove wind temperature can reach 1300 ℃.

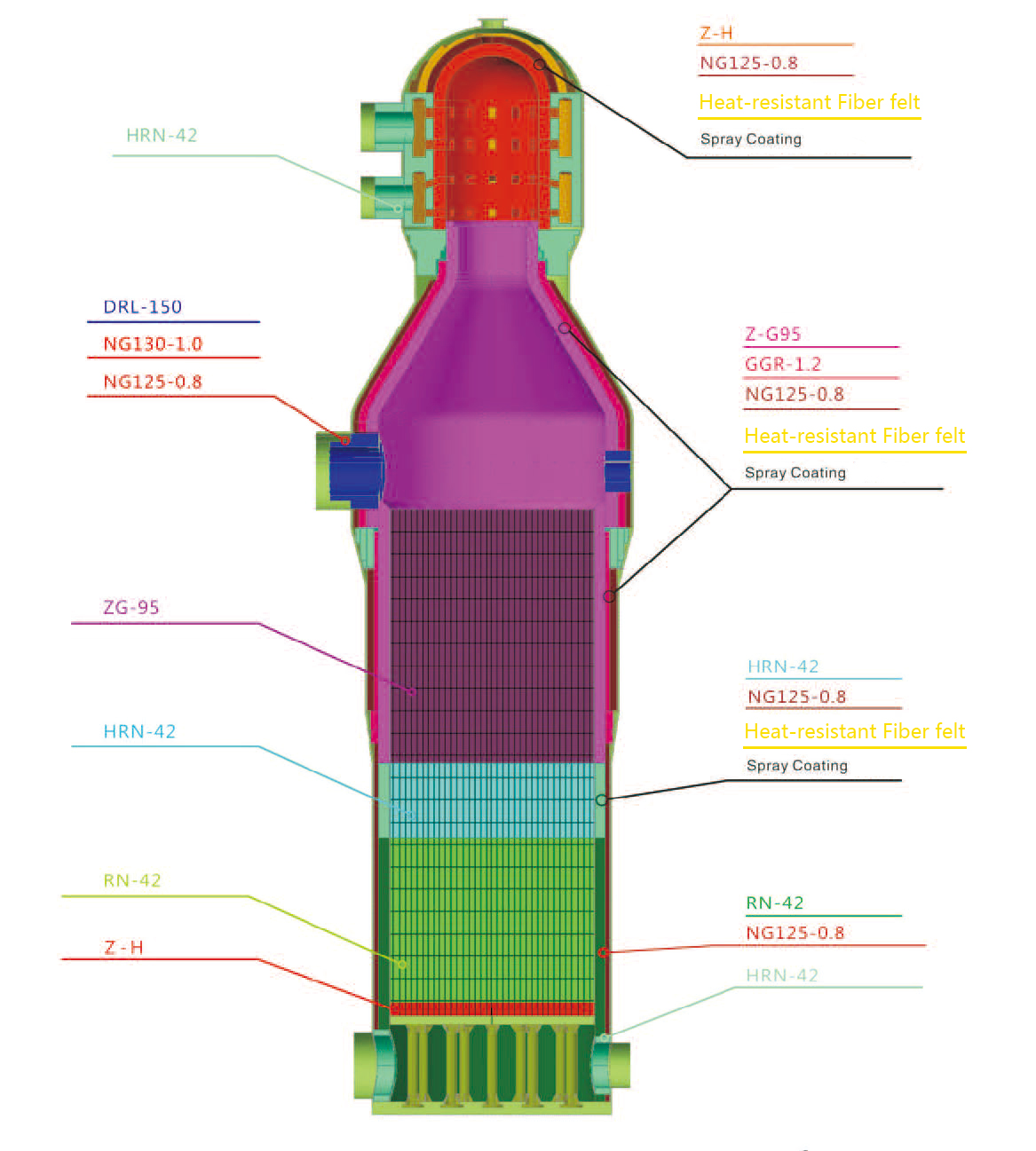

According to the stove type, Hot blast stove has top-combustion, internal combustion type, external combustion type, etc. It usually consists of heat storage room, combustion room, burner, hot air duct, etc.. According to the application area, the refractory material configuration as follows:

1, the lower part of the heat storage chamber: clay brick, heat-resistant concrete

2, the middle of the heat storage chamber: low creep clay bricks, high alumina bricks, low creep high alumina bricks

3, the upper part of the heat storage chamber: low creep high alumina bricks, silicon bricks

4, combustion chamber: low creep high alumina bricks, silicon bricks

5, burner: clay bricks, cordierite - mullite bricks

6, hot air duct: low creep high alumina bricks

| Refractory Datasheet for Hot Blast Stoves | ||||||

| Project | Clay brick | High alumina brick | Silica brick | low creep clay brick | Low creep high alumina brick | Cordierite-mullite brick |

| RN | RL | RG | RDN | RDL | RMJ | |

| Al2O3;% | ≥42 | ≥65 | / | ≥42 | ≥65 | ≥50 |

| SiO2;% | / | / | ≥94 | / | / | / |

| Fe2O3;% | ≤2.0 | ≤2.0 | ≤1.5 | ≤2.0 | ≤2.0 | ≤2.0 |

| Refractoriness;℃ | ≥1700 | ≥1750 | ≥1790 | ≥1750 | ≥1790 | ≥1750 |

| Apparent porosity;% | ≤24 | ≤22 | ≤22 | ≤22 | ≤21 | ≤25 |

| Bulk density;g/cm3 | ≥2.15 | ≥2.35 | ≥1.8 | ≥2.15 | ≥2.5 | ≥2.20 |

| Cold crushing strength;Mpa | ≥35 | ≥50 | ≥35 | ≥40 | ≥60 | ≥50 |

| 0.2MPa refractoriness-under-load/℃ | ≥1400 | ≥1500 | ≥1650 | ≥1420 | ≥1500 | ≥1420 |

| Creep rate;% (0.2Mpa,50h) |

/ | / | 1550℃ ≤0.8 |

1250℃ ≤0.8 |

1450℃ ≤0.8 |

1250℃ ≤0.8 |

| Permanent linear change on heating;% | 1300℃×2h 0~-0.4 |

1400℃×2h +0.1~-0.4 |

/ | 1400℃×2h +1~-0.2 |

1450℃×2h +0.2~-0.2 |

1350℃×2h +0.2~-0.2 |

| Thermal shock stability; times (1100℃, water cooling) | / | / | / | / | / | ≥70 |

| Real density;g/cm3 | / | / | ≤2.33 | / | / | / |

| Thermal expansion rate (1000℃);% | / | / | ≤1.26 | / | / | / |

| residual quartz;% | / | / | ≤1.0 | / | / | / |

| Application | Lower part of regenerator | middle part of regenerator | Upper part of regenerator, combustion chamber | middle part of regenerator | Upper part of regenerator, hot air duct | burner |

| Refractrory Datasheet for Hot Blast Stoves | |||||||||

| Item | Heat-resistant concrete | Spray paint |

Castable | Spray paint | Ceramic wear-resistant castable | Mullite mud | High alumina mud | clay mud | |

| YA | FL-130 | FN-130 | LT-Ja | TCJ-2 | MP-55 | LN-65 | NN-38 | ||

| Al2O3;% | ≥35 | ≥40 | ≥40 | ≥35 | ≥75 | ≥55 | ≥65 | ≥38 | |

| Bulk density;g/cm3 | ≥2.0 | ≥2.0 | ≥2.0 | ≥1.4 | ≥2.5 | / | / | / | |

| Cold crushing strength;Mpa | ≥20 | ≥20 | ≥30 | ≥20 | ≥70 | / | / | / | |

| Modulus of rupture;Mpa | ≥3.0 | ≥3.0 | ≥5.0 | ≥3.0 | ≥10 | / | / | / | |

| Room temperature bonding strength;Mpa | / | / | / | / | / | ≥2.0 | ≥1.0 | ≥1.0 | |

| bonding time;(min) | / | / | / | / | / | 1~2 | 1~2 | 1~2 | |

| Grain size;% | -1.0mm | / | / | / | / | / | ≥100 | ≥100 | ≥100 |

| -0.076mm | / | / | / | / | / | ≥60 | ≥50 | ≥50 | |

| Use part | Hearth foundation | Hot blast stove shell | Hot air stove drag coil | Hot stove flue | Hot air outlet, hot air duct | burner | Regenerator | Regenerator | |